the Power You Can Trust

Delivering Reliable,Efficient,and High-Performance Electrical Soloution for a Brighter Future.

Industry

Quality Assurance

Services

Krishna Electrical Motor

About

This is the heading

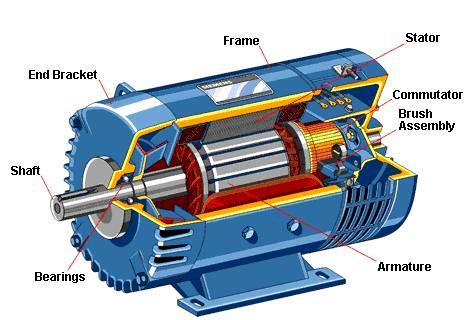

Industrial electrical motors are essential for converting electrical energy into mechanical energy, powering machinery across various industries such as manufacturing, transportation, mining, and construction. They are classified into AC motors, DC motors, servo motors, and stepper motors, each serving different applications based on efficiency, speed, and torque requirements.

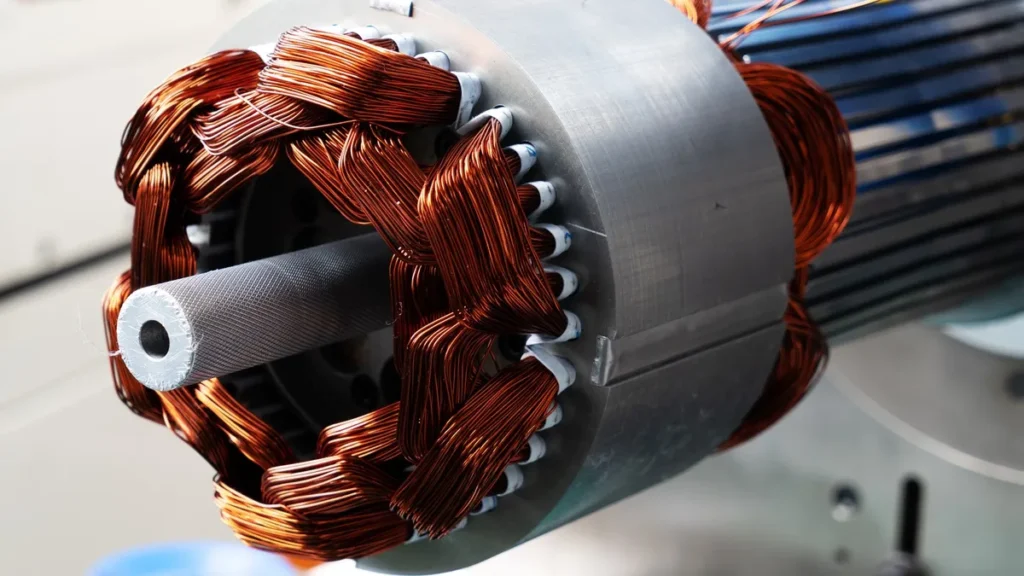

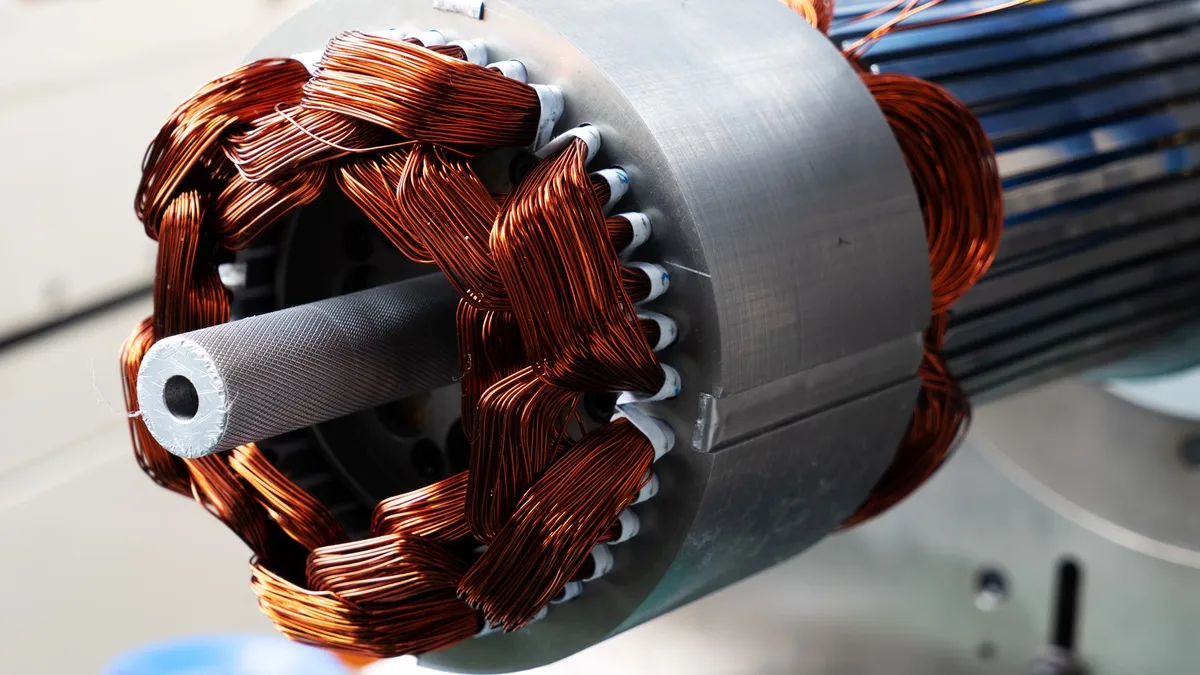

Stamping and Winding in Industrial Electric Motors

Stamping and winding are two critical processes in the manufacturing of industrial electric motors, directly affecting efficiency, performance, and durability.

Stamping refers to the process of creating thin laminations of electrical steel, which are stacked to form the stator and rotor cores. These laminations reduce energy losses due to eddy currents, improving motor efficiency. The stamping process involves precision cutting of silicon steel sheets using high-speed presses, ensuring uniformity and minimizing magnetic losses. High-quality stamping results in better motor performance, reduced heat generation, and lower energy consumption.

1 HP Industrial Electric Motor: Overview & Specifications

A 1 HP (Horsepower) motor is a widely used electric motor for small to medium industrial and commercial applications. It converts electrical energy into mechanical motion with a power output of 746 watts (1 HP = 746W). These motors are available in various types, including AC induction motors, DC motors, and BLDC motors, depending on the application and power requirements.

Type

AC Induction Motor (Single-phase / Three-phase)

- Single-phase: Used in household and light industrial applications like pumps and fans.

- Three-phase: More efficient, used in industrial machinery, compressors, and conveyor belts.

DC Motor (Brushed / Brushless)

- Brushed: Simple design, used in lifts and automation systems.

- Brushless (BLDC): High efficiency, low maintenance, used in CNC machines, robotics.

Servo and Stepper Motors

- Used in precise motion control applications like robotics and CNC machines.

Winding involves placing insulated copper or aluminum wires in the motor’s stator slots to create the electromagnetic field needed for operation. The winding process is crucial in determining motor characteristics such as power output, torque, and efficiency. There are different types of windings, including lap winding and wave winding, each suited for specific motor applications. Proper insulation, coil alignment, and impregnation with varnish enhance durability and prevent electrical breakdowns. Together, high-precision stamping and carefully designed winding ensure optimal motor efficiency, reducing energy losses and enhancing performance in industrial applications such as railway lifts, pumps, compressors, and automation systems.

Krishna Electrical Motor Started Since 2014 Growing Business

- Power Output: 1 HP = 746 Watts

- Voltage: Available in Single-phase (110V/220V) or Three-phase (230V/415V)

- Speed: Typically 1440 RPM or 2880 RPM, depending on the pole configuration (2-pole, 4-pole)

One Horse Power is defined as the amount of work that can be done by a standard horse in one second. In the International System of Units (SI) the electrical equivalent of one horsepower is equal to 746 watts.

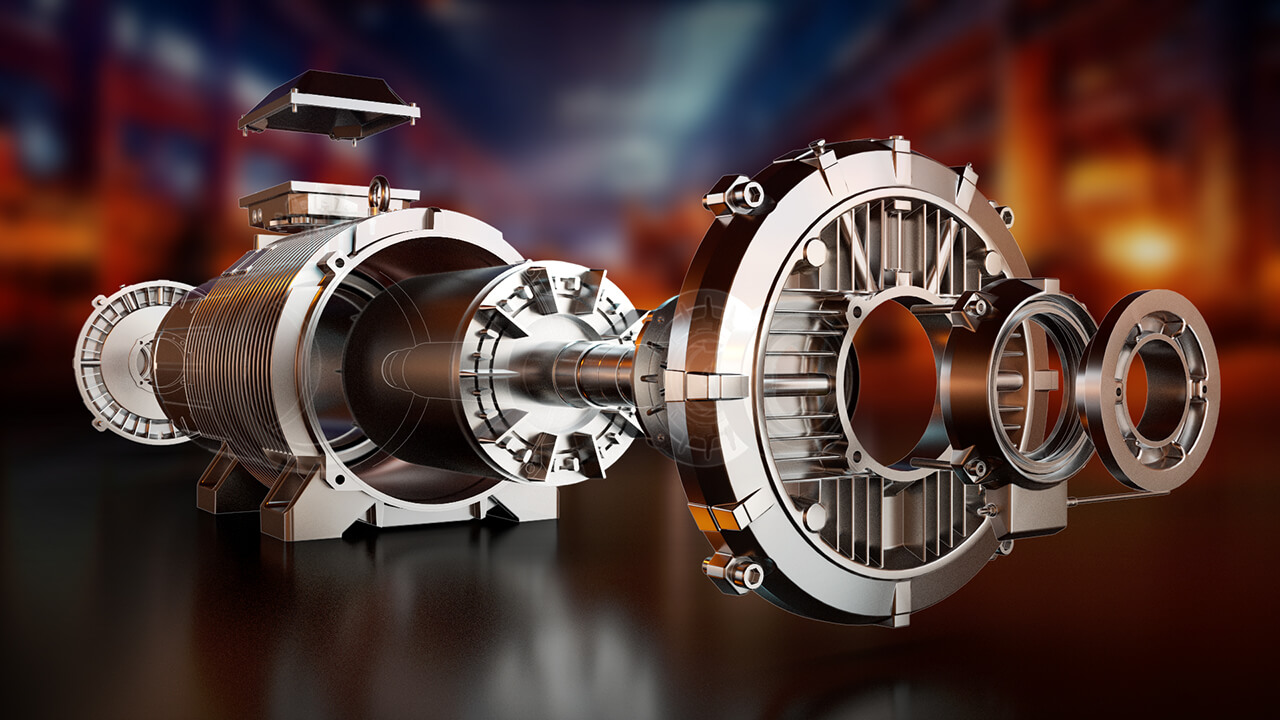

Assemble motor

Rotar

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Minima incidunt voluptates nemo.

Dashrath mandel

Ram parvesh

My DesignationAdd team member details here

Raj kumar

My DesignationAdd team member details here

Raj kumar

My DesignationAdd team member details here

Ram Kumar

My DesignationAdd team member details here

Rajesh kumar

My DesignationAdd team member details here

Amresh kumar

My DesignationAdd team member details here

Review Text

Testimonial #2 Designation

Review Text

Testimonial #3 Designation

Review Text

Testimonial #1 Designation